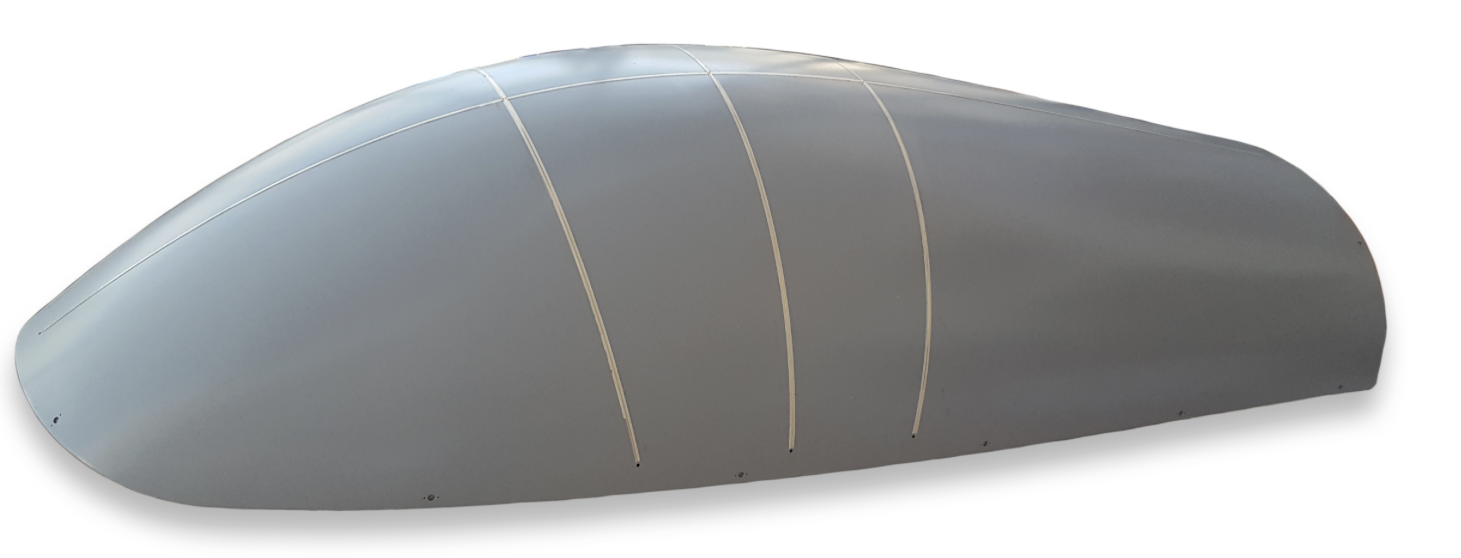

Kanfit's three-meter long radome (radar dome) prototype for satellite communications applications for flying platforms.

Trying new ways to produce a product has resulted in many positive results. Now there's a new way that a radar dome was created by Kanfit Ltd. The company manufactured a three-meter long radome, or radar dome, in an autoclave using quartz epoxy prepreg materials. "Prepreg" is the common term for a reinforcing fabric which has been pre-impregnated with a resin system. This resin system (typically epoxy) already includes the proper curing agent. As a result, the prepreg is ready to lay into the mold without the addition of any more resin. In order for the laminate to cure, it is necessary to use a combination of pressure and heat.

The follow up mechanical and physical tests on the prototype were performed at Kanfit’s in-house laboratories prior to its delivery to the customer and all have tested without problems.

Shai Fine, General Manager of Kanfit said, “We were approached by the customer due to our track record with composite materials. Thanks to our experience, we have been able to successfully extend our composite manufacturing capabilities to manufacture radomes in autoclave. This continues our long tradition of radome manufacturing by RTM and wet layup.

“It was a complicated project with many variables—from design to models and tools to prototype. There were multiple issues that needed to be addressed related to the radome’s physical, mechanical and electrical properties which significantly affect its performance. Together with the customer we were able to understand and overcome these issues within a short period of time.”

The radome prototype is currently undergoing final testing, and once completed, serial production is expected to begin in Q4.