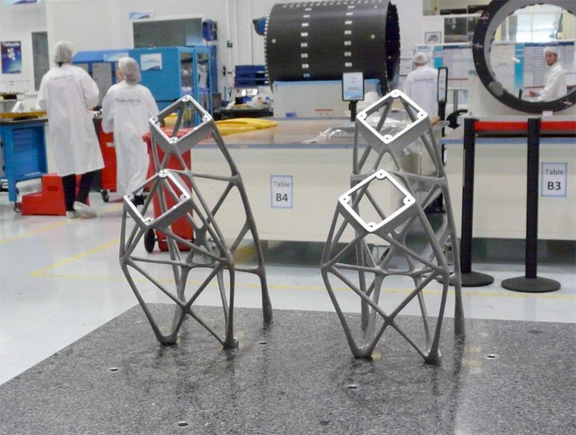

[Satnews] The Koreasat 5A and Koreasat 7 telecommunications satellites currently under construction by Thales Alenia Space will include the largest spacecraft parts ever made in Europe using a 3D printing technique called the “powder bed additive manufacturing process.”

Measuring some 45cm by 40cm by 21cm, these telemetry and command antenna supports are made of aluminum. The parts for the two satellites are identical and were made in the same batch by the same machine. Thales Alenia Space uses the Concept Laser Xline 1000R 3D printer, the largest laser beam melting machine in Europe, belonging to Poly-Shape, a French company and partner of Thales Alenia Space.

These two parts, featuring an innovative bio-design, have just passed their vibration acceptance tests, demonstrating perfectly reproducible dynamic behavior. Using 3D printing technology on this type of part offers a number of advantages, including 22% weight savings, a decrease in the production schedule of around one or two months, about 30% cost savings, and higher performance. An antenna support of this type is already in orbit since April 2015 on the TurkmenAlem satellite also built by Thales Alenia Space. The Arabsat 6B satellite, scheduled for launch from the Guiana Space Center in French Guiana in November, includes 3D-printed tripods.

One of Thales Alenia Space's primary strategic objectives is the transformation of its industrial capabilities, also an indispensable step for the company to meet evolving market demand in terms of cost and deadlines. Thales Alenia Space is deploying innovative technologies as part of this overall approach, while also maintaining people at the heart of the production process. This approach is reflected in the increasing use of additive manufacturing, as well as robotic and collaborative robotics or “cobotics”.