[SatNews] It's a memorable event when major companies become partners, but add to that the attendance of the President of France, Dutch Prime Minister, and Minister of Economic Affairs...

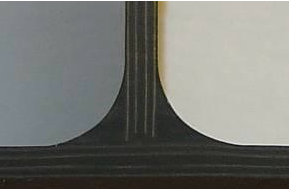

Cross-section of a Fokker thermoplastic butt joint

Koninklijke Ten Cate NV, Fokker and TenCate and partners enter next stage in innovation partnership with Airbus. Airbus, Fokker and TenCate signed the contract for the next stage of the Thermoplastic Affordable Primary Aircraft Structure innovation program (TAPAS), in the presence of the French President François Hollande, the Dutch Prime Minister Mark Rutte and Minister of Economic Affairs Henk Kamp. This program exists since 2010, and is a highly successful tool for project-based innovation partnership.

The TAPAS consortium consists of companies and knowledge institutes in the Dutch aerospace industry working together with Airbus on the development of thermoplastic composite applications in aircraft fuselages, wings and tail sections. The fruitful partnership between Fokker Aerostructures and TenCate Advanced Composites with Airbus and the other partners started in 2010 and, following the new extension, will run until end-2017.

The TAPAS consortium consists of companies and knowledge institutes in the Dutch aerospace industry working together with Airbus on the development of thermoplastic composite applications in aircraft fuselages, wings and tail sections. The fruitful partnership between Fokker Aerostructures and TenCate Advanced Composites with Airbus and the other partners started in 2010 and, following the new extension, will run until end-2017.The innovation partners within TAPAS from Dutch SME's are Airborne Composites, CODET, DTC, KE-Works, KVE and Technobis Fiber Technologies. The Netherlands National Aerospace Laboratory (NLR), Delft University of Technology and the University of Twente are the Dutch knowledge partners in this innovation program. The budget for TAPAS 2 is 24.3 million euros, and the Netherlands Ministry of Economic Affairs is supporting the ongoing partnership with a loan of 9.5 million euros.

Thermoplastic composites are advanced materials offering weight savings of 15 percent compared with traditional aircraft materials, together with benefits that include more efficient processing in production, lower costs of structural components and a high level of fire safety. These composites have high strength, light weight and contribute to the drive towards sustainable aviation, because the use of these materials allows constant reductions in aircraft weight to be achieved. As a result fuel consumption is reduced, the range of the aircraft is increased and higher payloads are possible. The target is to further increase the proportion of thermoplastic composites in current aircraft as well as in the new generation of aircraft. A demonstration tail section made entirely of thermoplastic composite material is being developed under the TAPAS 2 agreement. A thermoplastic fuselage panel has been produced and presented as demonstrator as part of TAPAS 1.

The Dutch aerospace industry holds a leading position worldwide in lightweight material applications. This position is due partly to the excellent national knowledge infrastructure in the aerospace industry, materials and processes. Partnership with customers, suppliers, universities and knowledge institutes in innovation platforms, supported by active government policy, shows how this structured approach is taking new technology developments to the next level.

Thermoplastic Affordable Primary Aircraft Structure (TAPAS). This consortium involves Dutch industrial companies and knowledge institutes working together with the aircraft manufacturer Airbus. The partners are jointly active in the aerospace industry, and work closely together with Airbus in the areas of materials, production and bonding technology and design. Development of the thermoplastic composites technology focuses on future Airbus applications, including primary structural components such as the fuselage and wings.

Fokker Aerostructures is a business unit of Fokker Technologies and internationally recognized as a first-class specialist in advanced, lightweight structural components for aircraft. With 4,950 employees worldwide, Fokker Technologies holds a unique position as specialist in the aviation and aerospace industry in the field of aerostructures, electrical systems, landing gear, maintenance, modifications and integrated service concepts.

TenCate Advanced Composites is a leading developer and producer of thermoset and thermoplastic prepreg composites for space and aerospace and industrial applications. TenCate Advanced Composites has production facilities in North America and Europe and representations in Asia.

Royal Ten Cate (TenCate) is a multinational company that combines textile technology with related chemical processes and material technology in the development and production of functional materials with distinctive characteristics. Products of TenCate are sold worldwide. Systems and materials from TenCate come under four areas of application: safety and protection, space and aerospace, infrastructure and the environment, and sport and recreation. TenCate occupies leading positions in protective fabrics, composites for space and aerospace, antiballistics, geosynthetics and synthetic turf. TenCate is listed on the NYSE Euronext (AMX), Amsterdam, the Netherlands.