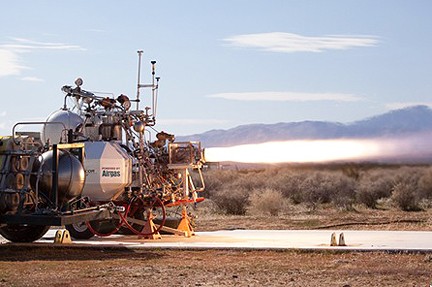

XCOR test fires its Lynx 5K18 engine with lightweight aluminum nozzle; United Launch Alliance (ULA) and XCOR to apply the nozzle and XCOR's liquid hydrogen (LH2) pump technology to new LH2 engine development. (Photo Credit: Mike Massee / XCOR)

United Launch Alliance (ULA) and XCOR Aerospace have announced their successful hot-fire demonstrations of a lighter-weight, lower-cost approach to liquid-fueled rocket-engine vacuum nozzles. The new nozzle technology, which uses aluminum alloys and innovative manufacturing techniques, is projected to be less costly and save hundreds of pounds of mass compared to nozzles in use today in typical large upper-stage rocket engine systems. Under a 2010 joint risk-reduction program by XCOR and ULA, ULA facilitated an accelerated demonstration of the nozzle technology, which was developed in XCOR's Lynx reusable, suborbital-vehicle technology program. ULA sought to determine the nozzle technology's applicability to future expendable launch vehicle programs. Earlier in the same risk-reduction program, XCOR demonstrated the ability to pump liquid hydrogen (LH2) using cryogenic piston-pump technology it developed for the Lynx suborbital vehicle. Based on the results of these successful technology demonstrations, ULA has now announced a larger follow-on program with XCOR to develop a liquid oxygen (LOX)/LH2 engine.

XCOR Lynx 5K18 main engine being prepped for a test series. Photo courtesy of XCOR.

The demonstrations just announced are from integrated engine/nozzle test firings with XCOR's Lynx 5K18 LOX/kerosene engine. The engine/nozzle combination demonstrates the ability of the aluminum nozzle to withstand the high temperatures of rocket-engine exhaust over numerous tests, with no discernable degradation of the material properties of the alloys. The tests validated the design, materials and manufacturing processes used in the nozzle, and laid a foundation for scaling the design to EELV-sized engines. The results also demonstrate the reusability of the engine and nozzle combination which is essential for low-cost, daily suborbital flights by the Lynx and other vehicles. ULA homepage. XCOR homepage.