motivating Winegard Company to get its WX980 and WX1200 VSAT antenna systems and controllers certified for use in more foreign countries. That list includes 32 nations in Europe, Asia, South America and North America where there is a growing interest in operational installations of the Winegard VSAT systems from its customers. On that list are countries as diverse as Canada and Mexico, as well as India, Ecuador, Algeria, Malaysia, Congo, Angola, Argentina and Australia.

The VSAT units already have received certifications from the European Union (CE), the Commonwealth of Independent States comprised of the 12 nations of the former Soviet republics, including Russia (GOST-R), and the Peru MTC (Peru Homologation).

Winegard customers currently using VSAT units in various parts of the United States want to use them abroad, because they like the reliability, ruggedness and cost effectiveness of the antennas. Each nation must individually certify the equipment for safe use, a process that typically takes from six to twelve weeks per country.

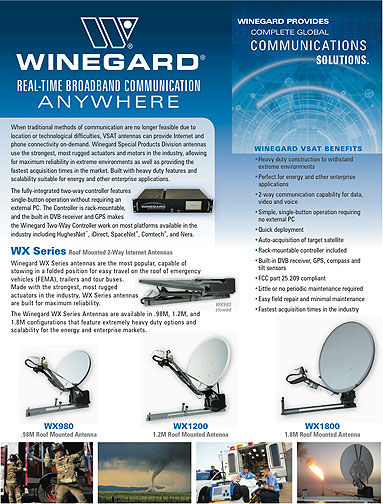

Generally, certifications for communications devices issued by foreign nations formally declare that the equipment complies with applicable standards or regulations that allow them to be safely sold in those countries. That includes such items as safety, environmental protection, electromagnetic interference and health. The certification denotes that the products also have been examined and approved by an appropriate conformity assessment body. Designed for the most extreme environments, these VSAT systems are primarily deployed on the roofs of emergency and first responder vehicles, tour buses and trailers. Most recently, Winegard has created a skid that permanently houses a WX1200 antenna as an ideal communications solution for land based oil and gas drilling sites.

Thousands of Winegard VSAT antenna systems and controllers are operational worldwide, including the countries of United Arab Emirates, South Africa, Iraq, Pakistan, Saudi Arabia, Scotland and Columbia.

Winegard’s manufacturing facilities, featuring state-of-the-art high-speed automated manufacturing, assembly and packing equipment, operates under the Lean Continuous Improvement model. This systematic approach to the elimination of process variation and waste continues to elevate quality, lower total cost, and shorten customer order fulfillment times.