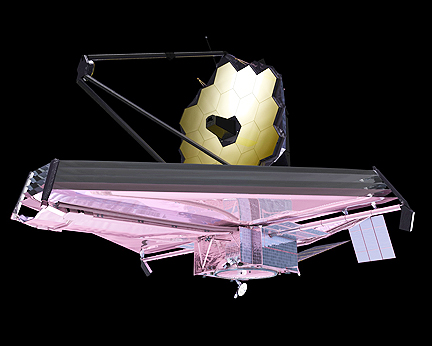

Artist conception of the James Webb Space Telescope, courtesy of NASA

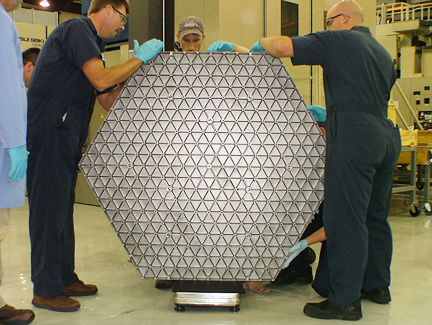

One of the primary mirror segment blanks. This image shows the back of the mirror blank, which is carved out in this pattern to make the mirror segment light, yet maintain its integrity. Photo credit: AXSYS

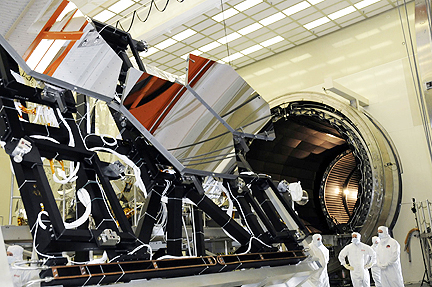

A team of engineers and technicians from NASA and Ball Aerospace & Technologies Corp. of Boulder, Colorado, prepare to load three James Webb Space Telescope mirror segments into a test chamber in the X-ray & Cryogenic Facility at NASA’s Marshall Space Flight Center in Huntsville, Alabama. There, they will subject the segments to temperatures reaching minus 414 degrees Fahrenheit — ensuring the mirror segments can withstand the extreme temperatures of space. The Webb Space Telescope is scheduled to launch to space in 2014 to study the formation of the universe and the evolution of our solar system. Photo credit: NASA/MSFC

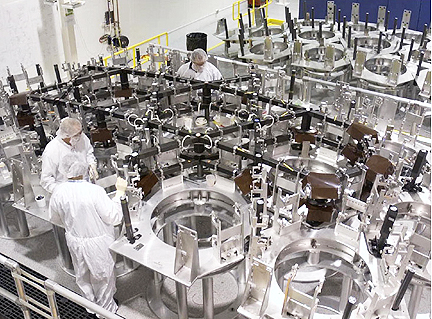

Although the MCDR approved the telescope design and gave the official go-ahead for manufacturing, hardware development on the mirror segments has been in progress for several years. Eighteen primary mirror segments are in the process of being polished and tested by Ball Aerospace & Technologies Corp. in Boulder, Colorado. Manufacturing on the backplane, the structure that supports the mirror segments, is well underway at Alliant Techsystems, or ATK, in Magna, Utah. This month, ITT Corp. in Rochester, New York, demonstrated robotic mirror installation equipment designed to position segments on the backplane. The segments' position will be fine-tuned to tolerances of a fraction of the width of a human hair. The telescope's sunshield moved into its fabrication and testing phase earlier this year.

The Pathfinder Composite Backplane for the Primary Mirror Segments being bonded at ATK. In the background is the flight backplane assembly structure. Photo courtesy of ATK.