European Space Agency... Mirror, Mirror, Mirrors Everywhere (Imagery)

[SatNews] ESA's mission to measure the precise positions of a billion stars reached an important milestone on September 3rd with the delivery of its first primary mirror.

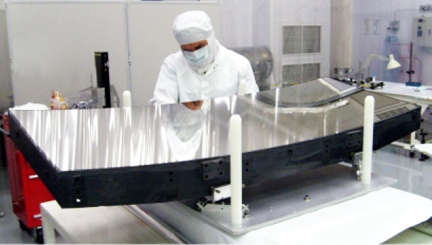

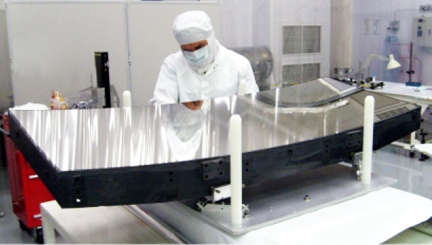

One of the Gaia primary (M1) mirrors, pictured at the premises of Sagem, France. Image courtesy of Sagem, France.

One of the Gaia primary (M1) mirrors, pictured at the premises of Sagem, France. Image courtesy of Sagem, France.

The second primary mirror is near completion and scheduled to arrive at the Toulouse test and integration centre of prime contractor

EADS Astrium during October.

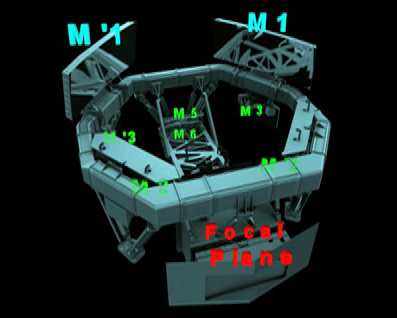

Gaia will carry two identical telescopes, each fitted with four mirrors (M1 to 4). A further two mirrors (M5 and 6) will send the light from these dual instruments into the same focal plane. To date, six of the 10 rectangular mirrors have been delivered. They are: the M3A tertiary mirror, whose dimensions are 0.65 x 0.275 m; both of the M4 combiner mirrors (dimensions 0.19 x 0.07 m), and the M5 and M6 mirrors (dimensions 0.54 x 0.36 m), in addition to the M1A primary mirror (dimensions 1.49 x 0.54 m).

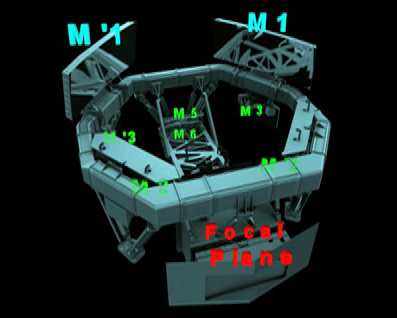

Three-dimensional view of Gaia's payload module with the telescope elements and focal plane indicated. The two primary mirrors (M1 and M'1) each measure 1.45m x 0.5m and rest on top of the optical bench, with the mirrors and structural support all made out of ultra-stable silicon-carbide material. Image copyright ESA.

Three-dimensional view of Gaia's payload module with the telescope elements and focal plane indicated. The two primary mirrors (M1 and M'1) each measure 1.45m x 0.5m and rest on top of the optical bench, with the mirrors and structural support all made out of ultra-stable silicon-carbide material. Image copyright ESA.

All of the mirrors have been fabricated from blanks made of

sintered silicon carbide (

SiC), a relatively new material in mirror fabrication for space missions. The blanks were made by

Boostec in France. Silicon carbide was selected as it allows each mirror to be extremely strong and rigid, but lightweight and with a high thermal conductivity — important not only for its on-orbit performance, but also for minimising deformations caused by Earth's gravity during ground testing. Each primary mirror is shaped by the French company

Sagem (located close to Paris), using computer-guided milling and polishing machines, and weighs about 40 kg. To achieve sufficient smoothness, all of the mirror blanks were coated with a thin layer of silicon carbide by chemical vapour deposition before polishing started. This process was carried out by

Schunk Kohlenstofftechnik in Heuchelheim, Germany. The polishing is a slow, painstaking process which requires each mirror to be polished to a precision of about 10 nanometres RMS. To appreciate this technical achievement, one can consider that if the

Gaia M1 mirror was scaled to the size of the Atlantic ocean, any bumps on the surface would be of the order of a few centimetres.

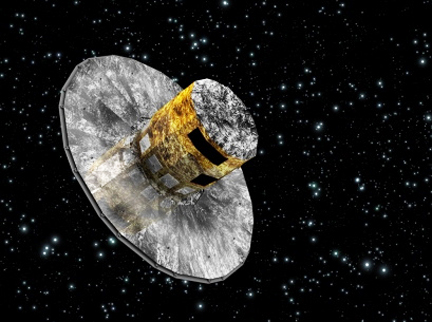

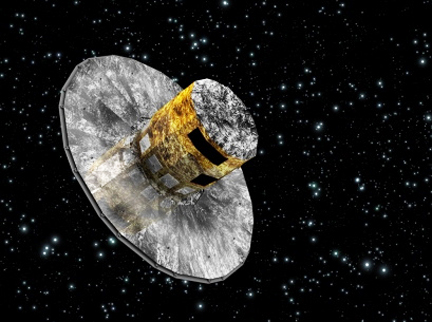

GAIA spacecraft

GAIA spacecraft

The mirrors also have an unusual curved shape, which is calculated using a very precise mathematical formula so that there will be no distortion of the incoming light across the telescopes' field of view and at all wavelengths from blue to red. After polishing, the surface is coated with enhanced silver reflective coating. This coating involves the addition of a dielectric amplification layer, which protects the silver from tarnishing and enhances its reflectivity across the entire spectral range (320 – 1000 nanometres) to be studied by Gaia. Gaia will view two widely separated areas of the sky, using two identical telescopes. Over its five-year mission, it will scan the entire sky, observing each of its target stars about 70 times. By accurately monitoring the two-dimensional star positions on the sky, it will be possible to infer their lateral motions across the sky and to calculate their precise three-dimensional locations, even for objects as far away as the galactic centre. Gaia will also measure the spectra of the brightest 15 percent of those stars, mainly in order to determine their radial velocities. Launch of Gaia on a

Soyuz-Fregat is currently scheduled for November 2012.

Topical Tags :

Regional Tags :