[SatNews] Optical Surfaces Ltd. has supplied a motorized 155mm aperture UV-VIS-NIR collimator system and...

[SatNews] Optical Surfaces Ltd. has supplied a motorized 155mm aperture UV-VIS-NIR collimator system and...

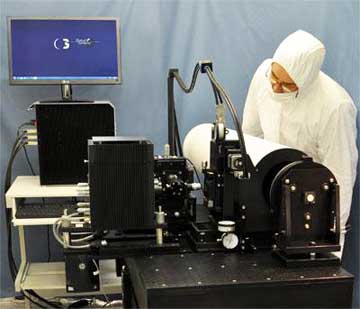

...interferometric alignment system to the Optical Information Systems Group at the Deutsches Zentrum für Luft- und Raumfahrt (DLR) in Berlin, Germany. DLR is Germany's national research centre for aeronautics and space. Its extensive research and development work in aeronautics, space, transportation and energy is integrated into national and international cooperative ventures. As Germany's Space Agency, the German federal government has given DLR responsibility for the forward planning and implementation of the German space program as well as international representation of Germany's interests.

Ilse Sebastian, Project Manager at DLR, said, "The primary aims of installing this new system in our class 100,000 clean room will be to enable broad-band diffraction limited imaging for MTF measurement, focusing and geometric calibration of single optics and focal planes, fully integrated camera systems and imaging spectrometers at wavelengths between 230 nm and 2.6 µm. Exact positioning of targets at the collimator focus is achieved using x,y,z step motors that deliver movement steps of better than 1 arc second. Thermal sensors incorporated into the body of the collimator will allow us to make measurements immune to operating temperature changes. To monitor and verify that the system is consistently in alignment—Optical Surfaces also designed and supplied a software-operated Laser Unequal Pathlength Interferometer (LUPI) system to interface with the collimator system". She added " We selected Optical Surfaces Ltd. for this important and challenging custom specified project because of its considerable expertise and experience in producing complete collimator assemblies based around high precision optics and its decades of experience which ensure that in mounting the optics, performance is not compromised".

Optical Surfaces Ltd. has been producing optical components and systems for more than 45 years and is now accepted as one of the world's leading manufacturers of high-precision optical systems for high power laser research facilities. The company's ISO 9001-2000 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions testing, particularly with long path lengths, becomes quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.