In late June, mechanical testing of the Gaia Payload Module was performed at the facilities of Intespace in Toulouse, France, under the direction of the Prime Contractor, Astrium. The results have been analyzed and the testing declared successfully completed. In order to verify the mechanical properties of the payload module and to prove that it can survive the launch, it was subjected to swept-sine and quasi-static load tests using an electrodynamic shaker. During swept-sine testing, the shaker excites the test subject with sinusoidal movements along the axis of interest at a slowly changing (two octaves per minute) frequency. Quasi-static testing simulates the effects of static loads on the structure by vibrating it at very low frequencies (well below the eigenfrequencies of the test subject).

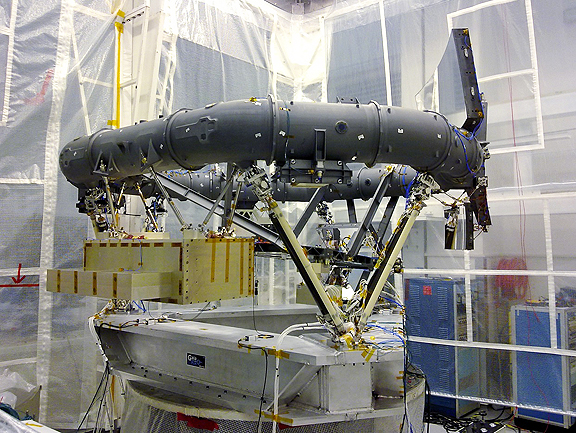

The Structural Model of the Gaia Payload Module in its X-axis test configuration at Intespace, Toulouse, France, during vibration testing. To verify the alignment, the optics of the Astro 1 telescope have been installed. Photo is courtesy of Astrium.

The primary structural component of the Gaia Payload Module is the optical bench, also known as the 'torus', which is constructed from 19 sintered silicon carbide components brazed together. The flight torus was mounted onto the test adapter on the shaker by its three flight model bipods. To allow verification of the optical alignment, the Astro 1 telescope was equipped with a full set of flight model mirrors (M1 to M3); the Astro 2 telescope mirrors were mass dummies. The flight models of the common mirrors (M4 assembly, M5, M6) were also installed for the test. Mass dummies represented all the other equipment (i.e., the Basic Angle Monitor, Radial Velocity Spectrometer, Focal Plane Assembly).

The Payload Module was fitted with accelerometers at critical locations to monitor its behaviour during the vibration tests. The swept-sine and quasi-static tests were performed on each of the module's three axes. Swept-sine testing was conducted at three levels: a low level survey (0.1g, swept from 2 kHz down to 0 Hz) which constitutes a reference test allowing unexpected frequency shifts or amplification changes to be detected; an intermediate level sweep (-3 dB referenced to qualification levels, swept down from 100Hz); and finally a sweep down from 100 Hz at qualification levels. The qualification levels varied from 0.2g to 3.5g, depending on the axis under test and the frequency. The excitation amplitude was notched (reduced) at the eigenfrequencies of the Payload Module, to prevent the structure from being subjected to forces not representative of the flight loads and beyond its design limits. When this was done, care was taken to ensure that the loads experienced during the test were still sufficient to match those expected during the launch.

Before the commencement of testing and after the completion of testing on each of the three axes, the optical alignment of the Astro 1 telescope was checked using theodolites. The required alignment accuracy was maintained during the tests, confirming that the telescopes will remain aligned as they experience the mechanical environments expected during transportation and launch.